Interchangeable Head Digital Torque & Angle Wrench

Sturtevant Richmont's new 1350 Exacta 2 is a highly versatile digital torque and angle wrench that will make a big impact in your assemblies. Essentially a slimmer version of the 1250 Exacta 2 series, its slim and streamlined body allows access to tighter areas. It weighs less than half the weight of the comparable 1250 Exacta 2 torque spanner, and the integrated shear beam sensor eliminates leverage sensitivity and ensures consistently accurate torque application.

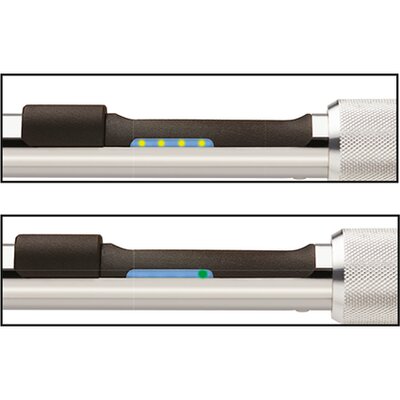

Visible from any angle, light bands on both sides of the wrench turn yellow, then green, the wrench beeps, and the handle vibrates when target torque is achieved. The display backlight activates when torque is applied.

All torque and angle settings (P-sets) are made with the Global 400 or Global 400mp torque controllers. No changes can be made on the control panel of the torque wrench. This fulfils another point of error-proofing, as unintentional changes are prevented. Up to four 1350 tools can be used simultaneously with a Global 400 / 400mp (can be used in combination with the 1250 Exacta wrenches).

Operator Guidance Using Colour, Sound, and Vibration

Operators receive error proofing by guidance from both the 1350 wrench and the controller. By establishing the Min Torque, you are also establishing the point at which the light band on the side of the wrench changes.

Features & Benefits

Four Modes of Operation

Scope of Supply

Options / Accs / Spares

Battery Notes

Quick Change Dovetail (QC)

For those applications where rapid and frequent head size changes are required SR offers the Quick Change heads. The regular dovetail use the pin and spring embedded in the dovetail. The Quick Change dovetail uses a ball bearing and spring which facilitates the use of thumb power. Rather than using a small, flat head screwdriver or our CART tool to depress the pin and remove the head, at customer request SR designed these wrenches to make a head change only using pressure from your thumb.

NOTE: The quick change dovetail should NEVER be used with any of the adaptors or extensions. This includes the J adaptor, the Y adaptor, the DIN style adaptor, the standard tooling adaptor, and any of the extensions.

Compatible Controllers

Interchangeable Dovetail Heads

| Model | Item No. | Torque Range [N·m] | Torque Range [lbf·ft] | Torque Range [lbf·in] | Tool Tang | OvL [mm] | Weight [kg] |

|---|---|---|---|---|---|---|---|

| 1350 Exacta 5 AA | R 10980 | 1.3 - 6.8 | 1 - 5 | 12 - 60 | Dovetail w Pin/Spring | 333 | 0.59 |

| 1350 Exacta 25 AA | R 10981 | 6.8 - 34 | 5 - 25 | 60 - 300 | Dovetail w Pin/Spring | 378 | 0.66 |

| 1350 Exacta 75 AA | R 10982 | 20 - 101 | 15 - 75 | 180 - 900 | Dovetail w Pin/Spring | 419 | 0.73 |

| 1350 Exacta 150 AA | R 10983 | 41 - 203 | 30 - 150 | 360 - 1800 | Dovetail w Pin/Spring | 502 | 0.84 |

| 1350 Exacta 250 AA | R 10984 | 68 - 339 | 50 - 250 | 600 - 3000 | Dovetail w Pin/Spring | 703 | 1.14 |

Note: Changed design (previously with AAA cartridge, now with AA battery compartment), therefore changed article numbers.

| Model | Item No. | Torque Range [N·m] | Torque Range [lbf·ft] | Torque Range [lbf·in] | Tool Tang | OvL [mm] | Weight [kg] |

|---|---|---|---|---|---|---|---|

| 1350 Exacta 5 AA QC | R 10986 | 1.3 - 6.8 | 1 - 5 | 12 - 60 | Dovetail QC | 333 | 0.59 |

| 1350 Exacta 25 AA QC | R 10987 | 6.8 - 34 | 5 - 25 | 60 - 300 | Dovetail QC | 378 | 0.66 |

| 1350 Exacta 75 AA QC | R 10988 | 20 - 101 | 15 - 75 | 180 - 900 | Dovetail QC | 419 | 0.73 |

| 1350 Exacta 150 AA QC | R 10989 | 41 - 203 | 30 - 150 | 360 - 1800 | Dovetail QC | 502 | 0.84 |

| 1350 Exacta 250 AA QC | R 10990 | 68 - 339 | 50 - 250 | 600 - 3000 | Dovetail QC | 703 | 1.14 |

Note: Changed design (previously with AAA cartridge, now with AA battery compartment), therefore changed article numbers.

Table showing specifications by the manufacturer. It is recommended to primarily use in medium performance range (approx. 1/3 to 4/5 of rated capacity). If you regularly worked close to the limit of load (maximum capacity), a larger model or tool might be more advisable.

All specifications without guarantee, errors and omissions excepted.