Hybrid Technology – Smart Assembly Solutions

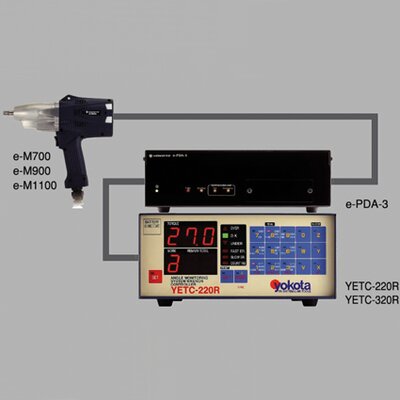

The YOKOTA electric system wrenches with integrated torque transducer and angle sensor offer a large reduction of energy consumption, a high degree of accuracy and fantastic work efficiency. Torque transducer and angle sensor located directly at the front of the main shaft, giving the best accuracy of measurement.

Faulty tightening detection with maximum accuracy due to the use of an integrated torque transducer and also an integrated angle sensor. During the tightening process, four different variables are measured and monitored: Torque - Angle - Time - Nº. of Impulses. Torque transducer measures directly and transmits the signals contactless. Detects cross threads, double hits, contamination, etc.

Special feature to prevent cross threaded tightening: reversely rotating a bolt to a preset angle at the start of tightening. Combinations of buzzers and LED (Green / Red) for operator feedback on OK / NOK tightenings.

The Motor speed freely adjustable in the controller. For three different speed stages: Start of trigger / Run down / Final tightening. The reaction forces are close to zero due to the use of oil impulse mechanism, even at high torque bolt tightening. Compared with older models, the number of bolt tightening is improved to 20 bolts/minute.

Controller Features

Sustainability